O’Dell Manufacturing History and Recollections

I owned a pet store in Bay City, Michigan in 1970 and had a very good customer named Clark O’Dell. He’d come in regularly and buy fish and as our friendship grew, we even split the cost of importing saltwater fish from a wholesaler in Florida. Through our friendship, Clark told Ken Hall the CEO of O’Dell to approach me to become a salesman for O’Dell.

In the early beginnings of O’Dell Mfg., Clark O’Dell was the first to consider using Dow Corning sealant to make an aquarium. He bought some from a “Door to Door” salesman selling the sealant to repair broken dishes. As an aquarium hobbyist, he decided to glue five pieces of glass together, and guess what, it worked. He originally built aquariums with a flat bottom and used window rubber seals to prevent cutting yourself on the edges of the glass. From there it innovated using painted black wood molding to decorate and cover up the look of the bottom of the aquarium. He started buying glass from a local glass company that specialized in home glass products. As his business grew, he ran up debt to the glass company and they took over the majority ownership, to settle the debt and to provide working capital. They hired Ken Hall as the new O’Dell CEO.

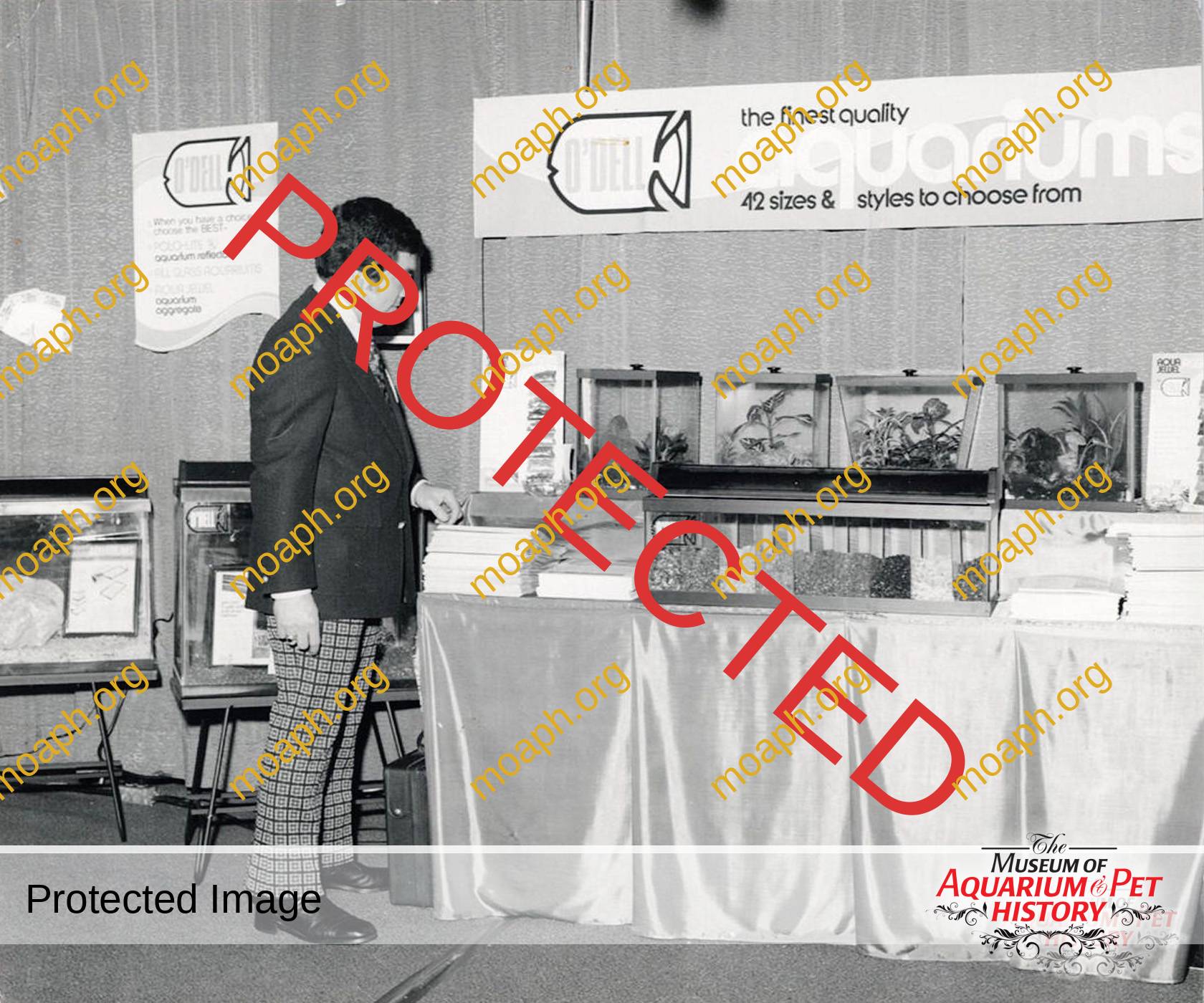

Ken Hall quickly realized he had to find a way to mass-produce aquariums, build a distribution network, and build a team to support the growth. He had a unique business background in plastic molding and metal works. Clark was experiencing returns from the flat bottom construction, so Ken decided to make changes. He was the first to develop a plastic frame to use on the bottom and top of aquariums. This was revolutionary because it solved two major issues. The first was to create the floating bottom, which prevented broken bottoms caused by uneven stands or countertops and provided more even support. Prior to the innovation of the plastic frames, aquariums were glued together and held together, until cured, by a wooden device to prevent the glass from moving until the sealant dried. The biggest advantage of the plastic frame was, it eliminated the use of wooden devices and 40’ long tables, that held the curing aquariums. With this new frame, we could build tanks, place them on pallets, holding 20 each, separated by cardboard and stacked six rows tall, and they could cure while in the warehouse. This allowed one person to produce 200 ten-gallon aquariums in one eight-hour shift.

Other innovations included, the one-piece top frame, could now comfortably hold a glass top firmly and Ken’s knowledge of plastics, led to extruded plastic parts, that provided the plastic hinge for the glass tops and the rear plastic piece that could be cut out to provide places for aquarium heaters, air tubing and other accessories. This then led to extruded plastic incandescent and florescent, nonflammable aquarium lights and full hoods. This was a great innovation to replace all the old metal aquarium lights, that were produced with the old metal framed aquariums. Extrusion was great because you could produce it in any length and cut it to the size needed. O’Dell also had a stand-alone metal cutting factory that began producing sturdy aquarium stands for any size aquarium and in a knockdown version.

So, we began a real revolution, cutting glass, sanding all edges, building aquariums with plastic frames, saving many man-hours, and using experienced hard-working employees, that came from the auto industry. This work ethic was important because this workforce was used to working long hours and was very willing to work around the clock, three shifts a day. We deliberately hired tank makers with thin fingers, who could always produce a clean, thin bead of glue in all corners. The biggest problem we had, was a big turnover of workers, every time the auto companies were hiring.

I was the first salesman O’Dell hired to cover the entire USA. I was selling 40’ truckloads of glass boxes in all states and our business grew dramatically. In the beginning, all aquariums came with black frames only. O’Dell was also the first to launch wood-colored frames. We would take black frames and apply a woodgrain-colored tape that was heat-sealed to each frame. This immediately required all customers to duplicate their inventories to carry two color options. With this came a demand for wood-colored aquarium stands and aquarium lights. The next big growth came from partnering with a local knockdown furniture producer to produce wood-grained colored aquarium stands. We launched a whole new range of stands for any size aquarium. With this growth we needed more sales help, so we hired Sal Pustizzi to cover the eastern USA.

While visiting California on a sales trip, I always visited and detailed pet stores. I began to see all wood aquarium stands, that were made of cured pine and then burned with a torch to show off the wood grain. I really liked the look but wasn’t fond of the burned finish. This was a time when the oak look began showing up in desks, cabinets, desk phones, office, and house doors. When I returned to the corporate office in Saginaw, MI, I suggested to management that we launch oak-colored aquarium frames, lights, and stands at the next APPMA show. We did this and had record sales that year at the show. Now all customers had three color options of aquariums, stands, and covers.

O’Dell began advertising in all trade magazines, working trade shows, and sales meetings. We felt a real need to grow the tropical fish hobby. We chose to do this in the traditional manner of promoting 10 gal aquariums for starter kits and funding 12 ½ hour TV shows, on PBS named Guppies to Groupers. We were lucky to partner with a PBS station in Erie, PA. Public TV stations are required to produce new programs yearly and submit them to corporate for possible national distribution. This is exactly how Sesame Street began. The station manager Bob Chittister loved tropical fish and his good friend Paul Spiece was a perfect host who kept fish his whole life. Guppies to Groupers began airing nationally on over 200 stations and creating a demand and awareness for keeping tropical fish. O’Dell supported the program for two years with funding and equipment. Paul Speice began to have Guppies to Groupers booths at trade shows and supporting aquarium societies.

O’Dell grew rapidly and expanded its size and began looking to expand its product range. Ken Hall developed a revolutionary plastic aquarium heater called the Hydraheat. It was 100% plastic, with a silicone oil-filled bottom barrel. As the oil heated the heating element, the oil expanded and caused the bellows to raise up and separate the upper contact points and turn the heater off. Our boss ordered large quantities of parts in a rush to market, without going through a vigorous testing program. We launched at the APPMA trade show and sold one hundred thousand units in assorted sizes. One major lesson we learned after more testing was that silicone oil stored in open containers would become airborne. While this happened, it would coat and adhere to the inventory of plastic parts. Even though the bottom barrel was electronically sealed, the oil coating on parts used, prevented a perfect seal. As a result, we began seeing big returns because the oil leaked out and rose to the top of the aquariums, that the heater was used in. Nobody likes to have an oil slick on the surface of their aquarium, so all the heaters sold at the show were returned. We attempted to fix this issue, relaunched, and failed again. This turned into a $1 million dollar failure and cost Ken Hall his job.

We always treated our employees fairly and gave the entire workforce turkeys at Thanksgiving, hams at Easter, and Christmas bonuses. Working in an area with a strong union presence was always an issue. We were competing with the auto industry with wages and benefits. Whenever the big three automakers were hiring, we lost employees. The day soon came when our O’Dell workforce decided to unionize, and we began looking for solutions. During a private meeting with the union, we told the union bosses that we couldn’t afford long term to live with their demands. They said frankly that they didn’t care what we decided and all they cared about was the increased union dues they would receive. They also said we could no longer give our employees anything free, as it would appear to be a bribe, to prevent unionizing. After that O’Dell decided moving our operation out of the area would be the answer to this problem.

Before we began the heater production, we also sold the company to a Chicago-based venture capital group. With the acquisition, came a lot of changes, which always happens with large investment firms. The solution to all problems began to be, that we had to cut overhead and increase profits. One of the new board members, found a ten-acre piece of land, with a 100,000 square foot building and a rail siding in Atlanta, GA. The building also had $100,000 worth of re-sellable equipment inside. So, O’Dell decided to relocate from Saginaw, MI to Atlanta, GA and only asked six employees to move south. I was one of the six and bought a house in Marietta, GA. Before moving to GA, I was offered a job with Marineland Aquarium Products in southern California and decided to move west.

When O’Dell made this move, they hired a new president, sold all the old equipment in the new warehouse, which paid for the property, and began to make major changes. The difference between the old employees and the new GA-based employees was tremendous. The workforce no longer wanted to work long hours or on weekends. It seemed that the slim fingers were replaced with larger farm fingers and the silicone seams became much wider and quality took a big hit. Being in the middle of a large carpet industry location, provided a new product opportunity. O’Dell began The Cat Craft brand of cat furniture, that utilized surplus cardboard posts, wood, and carpet. This was a big plus with growth potential.

During this period, O’Dell also opened a factory in Northern California. They began competing with an aquarium maker in Southern California and lost a lot of money. After a year and a half, they closed that facility down.

While O’Dell was having all their difficulty, the Ritzow Brothers at All Glass Aquarium Company in Franklin, WI was taking advantage of the O’Dell problems. I mention this because when I left Marineland Aquarium Products and became an independent rep in the western USA. I began selling O’Dell, but soon left and became an All-Glass Aquarium rep. I began switching distributors from O’Dell to All Glass distributors and wound up taking most of the O’Dell business.

After a few years, the investors sold O’Dell and the property. They made more money on the sale of the property than they ever made with O’Dell. The new owners of O’Dell lasted a few more years, separated Cat Craft, and closed O’Dell down. What was once a great brand, become only a memory.

I have many fond memories of my time with O’Dell and all the great people I worked with. We created a real revolution in the aquarium hobby and saw tropical fish keeping enjoy unparalleled growth. There was a time when every aquarium retailer had a stack of ten-gallon aquariums piled high with a starter kit inside. Every retailer like Sears, Montgomery Wards, Woolworths, K-Mart, and even Pier 1, had fish departments selling livestock. Mom and Pop aquarium stores and full-line pet stores enjoyed great growth. Our kids learned a lot from keeping tropical fish and goldfish about life and responsibility.